Cannabis has become a widely accepted form of medicine for patients across the United States. These patients, many of whom are immunocompromised, rely on testing laboratories to ensure the safety of the products they use. The lack of consistent and clear regulations makes this a challenging endeavor for cannabis testing reference laboratories like White Buffalo Laboratories in Montana. We reached out to Dr. Tyler Smith and Dr. Jonathan Speare, the founder and co-owner of White Buffalo Laboratories, to learn more about how they test for pathogens in their laboratory and what challenges they face while operating in the under-regulated and rapidly changing cannabis industry.

Q: What inspired you to start a cannabis testing reference laboratory?

A: Tyler is a stage III cancer survivor. His experiences with cancer naturally made him very aware of the need and benefit of cannabis as a medicine. After the November 2016 approval of I-182, a ballot initiative to expand Montana’s medical marijuana program and allow testing labs, Tyler founded White Buffalo Labs in 2017.

Together we feel our academic and professional experiences lend themselves perfectly to the demands of a cannabis testing laboratory. We have a well-informed and unique experience base to draw from to support the development of the cannabis industry. Between us, we have two doctorates in chemistry and nearly 20 years of manufacturing support experience including FDA regulated manufacturing environments, manufacturing of products affected by EPA regulations, and ISO 17025 contract testing labs. We also have nearly ten years of experience researching diseases including developing ultra-sensitive DNA-based diagnostic assays at the National Institutes of Health. We believe that cannabis has legitimate medicinal properties. We want to play a positive role in bringing safe and effective cannabis products to market and establishing Montana’s medical marijuana programs.

Q: Why should a grower utilize your services?

A: We offer our experience from other related environments to help growers produce safe and effective medicine on a consistent basis. Consistency includes offering products with uniform dosage. Our nationally recognized team is committed to advancing the cannabis ecosystem by promoting common sense regulation and consulting with clients to further develop the quality and safety of their products.

Q: What challenges do you face in the market due to current federal and state laws?

A: Setting up a lab from scratch requires a significant amount of funding. Federal rules make bankers understandably averse to financing anything to do with the cannabis industry. This results in persistent financial challenges for testing labs and growers.

State challenges include working with regulators who may have limited knowledge of pre-existing lab regulatory support frameworks such as ISO 17025 and cGMP/USP, which are traditionally overseen on a federal level. This lack of understanding leads to trust issues between regulators and labs when it comes to what is best for the consumer. State publications have no revision history, develop new rules often, misidentify compounds, and may provide ambiguous precision with limits. Additionally, regulators are still learning about the thorough process labs must go through to achieve accreditation and validation of methods.

Q: In your experience, how do cannabis testing laboratories benefit from ISO 17025 accreditation?

A: It’s a fantastic, rigorous framework that forces labs to operate in a controlled and consistent manner as well as maintain a mentality of continuous improvement. If a lab has ISO 17025 accreditation, regulators should be able to trust the lab is being held accountable for its testing and quality program management.

Q: Cannabis testing laboratories can use traditional culture methods or qPCR to detect pathogens. Could you describe the primary pros and cons for each method?

A: Pros of culture methods:

- USP <61> and <62> / FDA BAM are tried and true.

- Viability is readily apparent.

- Capable of performing multiple tiered confirmation process.

- Great for screening.

Cons of culture methods:

- Usually takes longer than qPCR methods.

- Growth promotion and method selectivity is challenging for some organisms.

Pros of qPCR methods:

- Relatively quick.

- High sensitivity.

- High specificity.

Cons of qPCR methods:

- Less amenable to general classes (e.g., total aerobic, yeast and mold)

- Reagents are more expensive.

- More sensitive to cross contamination.

- Not as amenable to orthogonal testing.

- Specific but not as multidimensionally specific as plating methods which allow morphological analysis and sub selection of colonies of interest with further identification.

Q: How do you use Microbiologics quality control products in your laboratory?

A: We use KWIK-STIK™ for growth promotion controls and verification, and Epower™ CRM for quantitative method validation including recoveries and uncertainty calculations.

Q: What changes do you anticipate in the next five years that will accelerate the cannabis testing industry?

A: Testing will be accelerated by consumer demand for more content metrics (e.g., terpenes) and safer products (e.g., broader list of pesticides). Regulators may become more familiar with the way FDA regulates drugs via USP which will drive more standard practices. Providers will gain an appreciation for quality metrics and will want to offer more refined quality information. National consensus for standard testing methods, like the current system in Canada, may emerge in 5-10 years (e.g., via USP) with each state given allowances for their own versions of the rules.

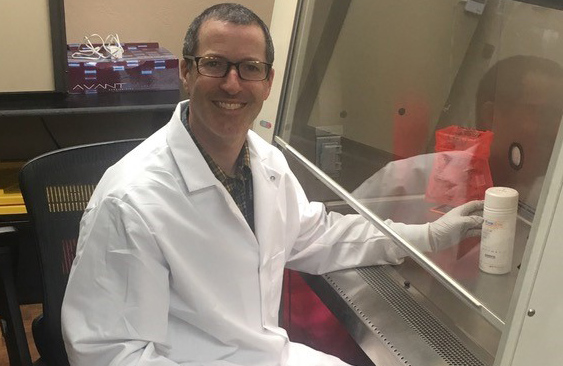

About Tyler Smith, Ph.D., Founder and Owner of White Buffalo Laboratories

Tyler grew up in Mississippi. After obtaining a B.S. in chemistry from Mississippi College, he moved to the Midwest to pursue a Ph.D. in the same field. He completed his Ph.D. under Professor D. Kiely at the University of Montana in 2008. While working in high level positions in both research and development and product development, Tyler was diagnosed with stage III testicular cancer. Tyler has been cancer free for nearly four years and uses his experiences to push for safer, more accessible cannabis derived alternatives to conventional therapeutics.

About Jonathan Speare, Ph.D., Co-Director and Co-Owner of White Buffalo Laboratories

Jon grew up in the Boston area. He received a B.A. in chemistry from Colorado College and went on to obtain a Ph.D. in chemistry from the University of Montana. Jon has over twenty year of experience working in research and development and quality control laboratories. He has extensive experience in cGMP drug and dietary supplement quality control and academic research laboratories with primary training in analytical chemistry, physical biochemistry, and cell and molecular biology.

Both Jon and Tyler moved West because of their love for mountains, rivers, and the community composed of great people that help them become better scientists.

Learn more about White Buffalo Laboratories by visiting their website or following them on Facebook.

Microbiologics offers microbial testing controls to help cannabis labs ensure accurate results and keep consumer safe. Visit our website to find the right strain and format for your lab.

Read Next – How Certified Reference Materials Help Labs Meet Regulatory Requirements

Useful info. Fortunate me I found your site by chance, and I’m

shocked why this coincidence did not happened earlier!

I bookmarked it.