Several factors can influence the accuracy of aerobic plate counts used to estimate the number of microorganisms in food, cosmetic, pharmaceutical, and household products. Below are a few best practices we recommend for achieving consistent and accurate counts.

1. Ensure the quality of the media

- Use appropriate media. Nonselective media is best for total aerobic counts. When testing for a specific category of microorganisms (e.g., coliforms), use media capable of detecting the target.

- Test the pH and confirm the purity of new batches of media.

- Perform quality control testing on new batches of media. This includes tests for growth promotion, inhibition and, when appropriate, indicative properties.

- Store media at the temperature recommended by the media manufacturer. Protect the media from excess light and humidity. Do not use plates that have been frozen or are wet.

- Do not use media past its expiration date.

- Do not reheat pour plate media after it has melted and re-solidified. According to the United States Pharmacopeia, molten media should be held in a 45° to 50° water bath for not more than eight hours.

- Control charts can be used to monitor quantitative testing of solid culture media. ISO 11133 explains how to use control charts for this purpose.

2. Monitor laboratory equipment

- Standardize instruments such as pH meters and spectrophotometers before use.

- Calibrate instruments such as thermometers and pipettes on a regular basis.

- Maintain incubators at the temperature specified by the test method. Check temperature at least twice daily. Validate their performance periodically (e.g., annually).

3. Faithfully follow the SOP

- The Standard Operating Procedure (SOP) for each aerobic counting method should be easily accessible to all laboratory personnel who perform the test. Review the SOP on a regular basis.

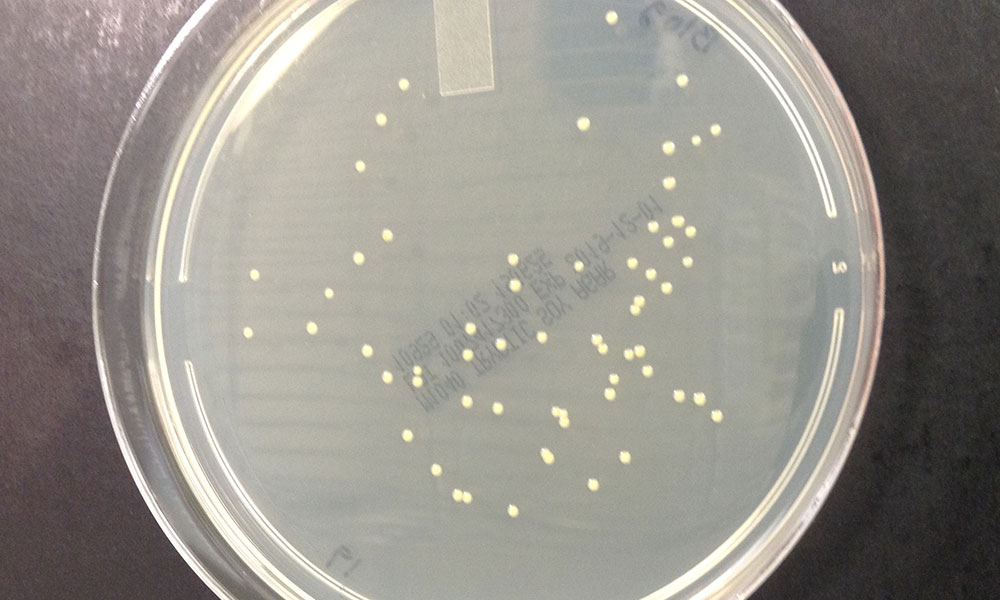

- Avoid high counts. Crowded plates are difficult to count and may inhibit the growth of some bacteria. For food samples, the FDA BAM warns that low counts (<25 colonies) may not be accurate.

- Test in duplicate or triplicate.

- Periodically perform a batch control.

- All results should be immediately recorded and routinely reviewed. The date and the name of the microbiologist performing the test should be recorded.

4. Get good samples

- Review the sampling plan periodically. Is the number of samples tested sufficient for the type of product being tested?

- In order to avoid unwanted contamination, samples should not be damaged or opened before testing.

- The SOP should list how often and when samples should be collected.

- The SOP should place limits on how long a sample can be held and at what temperature it should be stored.

- In order to avoid unwanted contamination, samples should not be damaged or opened before testing.

- Samples should be collected aseptically. Proper personal protective equipment (PPE) should be worn when collecting samples.

5. Train personnel

- Have a curriculum in place for training new technicians on why and how aerobic plate counts are performed. Document when the training takes place. New technicians should demonstrate proficiency before performing a test unsupervised.

- Routinely, test the competency of all laboratorians who perform aerobic plate counts by having an internal proficiency program in place.

- Instruct all personnel to use the same technique for tasks such as pipetting and pouring agar.

6. Prevent contamination

- Contaminated plates can distort results. In order to avoid contamination, the laboratory should have written procedures for cleaning counters, walls, and floors. The air should be routinely monitored.

- Equipment, such as incubators and water baths, should be cleaned on a regular basis to prevent contamination of test samples, media and supplies.

7. Carefully maintain microbiological cultures

- Quality control microorganisms should be acquired from a national culture collection or a qualified secondary supplier. Some manufacturers supply quantitative microorganism preparations including certified reference material (CRM). Uses for CRM include validation and verification of test methods. CRM is accompanied by a certificate detailing the strain’s identity, traceability, and the associated uncertainty.

- Avoid excessive sub-culturing.

- Store QC strains according to manufacturer’s instructions.

8. Follow the standards

The suggestions above are just a few ways laboratories can improve the accuracy of their aerobic counts. Whether you are testing food, cosmetics, pharmaceuticals, water or household products, we strongly recommend closely following the standards written for your industry.

Searching for CRM? Microbiologics is an accredited Certified Reference Material producer under ISO 17034:2016. Visit our website to learn more about our CRM products and industry-leading Quality System.

References

FDA (2001) – Bacteriological Analytical Manual – BAM: Best Practices

ISO 11133 (2014) – Microbiology of food, animal feed and water — Preparation, production, storage and performance testing of culture media

Personal Care Products Council (2016) – Microbiology Guidelines

Standard Methods for the Examination of Water (2015) – 9020 Quality Assurance/Quality Control

USP <1117> (2019) – Microbiological Best Laboratory Practices

0 Comments